With Tega, Take one-step ahead towards

- 100% efficiency

- 100% Clog-free operation

- 100% increase in life

- However, with 0% Stress.

Tega has more than 10,000 screen applications in gold, copper, iron ore, zinc mining, mineral processing, steel plants, cement plants, and aggregate industries. It stands as one of the leading manufacturers of screens and providers of screening services.

Configuration

- Achieved 98% efficiency and less than 2% clogging with our OptiNext panels.

- Delivered 150% more life in 100+ Trommel Screens with our OptiTrommel panels

- Expanded our production limit to 10000+ panels per year with Injection moulding technology.

- Continues improvement in our client’s existing application to deliver value with up-to-date requirements.

- Collaborated with our clients in our Tega Innovation lab to develop an innovative solution for complex problems.

Tega commits itself to deliver unique, highly efficient wear-resistant screen decks, which increases screening efficiency and life, reduces downtime and cost/tonne of material handling.

- Increase Screening Efficiency & throughput.

- Increase the life of the decks.

- Reduce the downtime of the screen machine with maximum availability for production.

Tega SLD Program

- S – Screening Efficiency Enhancement

- L – Life Enhancement

- D – Downtime Reduction

Tega’s SLD Program Implementation strategy

- Field-tested Screening solution for vibrating screens in Primary, Secondary and Tertiary applications.

- Reliable product quality with 45+ years of rich application knowledge in mining, mineral processing, and metallurgical plants.

- Value addition to client’s product processing operations by customization of process-specific and product-specific solutions. These include the selection of aperture, screen media material, and size as well as a fixing type to achieve the desired results.

- Continuous improvement in screen media design, new and improved fixing arrangements, new product development, and more adaptive solution techniques in line with customer’s requirements as per the variation in process parameters.

- Dedicated Service Team for Installation supervision and wear measurement to ensure performance validation and client satisfaction.

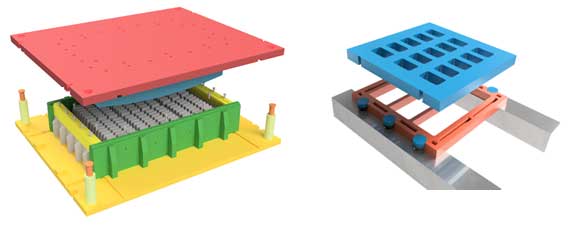

- OptiPrime©: Robust design to handle large lump size for optimum life and efficiency.

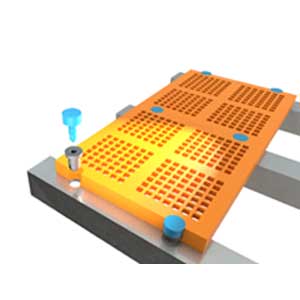

- OptiNext©: Easily replaceable and easy to handle, optimum life and efficiency, Manufactured in next-generation machines.

- OptiSlim©: Low thickness flexible panel to give optimum life and efficiency in highly moist environments.

- OptiTrommel©: Optimally designed Trommel structure for optimum flow, long life, and maximum ROI

- Scalping & Primary Screening Application – OptiPrime©, OptiNext©

- Secondary Screening – OptiNext©

- Tertiary Screening – OptiNext©, OptiSlim©

- Dewatering – OptiNext©

- Flipflo – OptiSlim©

- AG Mills, SAG Mills and Ball Mills Trommels – OptiTrommel©

- Scrubbers Trommels– OptiTrommel©

- Mining Plants (Iron Ore, Copper Ore, Gold Ore, Zinc ore, etc)

- Mineral processing plants (Iron ore processing plants, etc)

- Metal processing plants(Steel Plants)

- Coal Washeries

- Aggregate sector

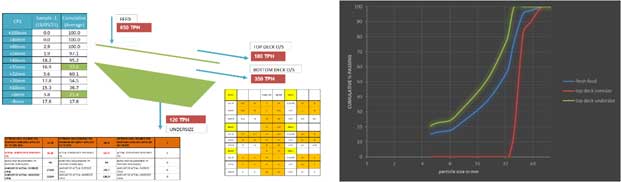

Engineering solutions are provided through our Propriety software/simulation packages used for Tega Screen Deck Designs

The Propriety software used are:

- SimEff - Optimize Efficiency

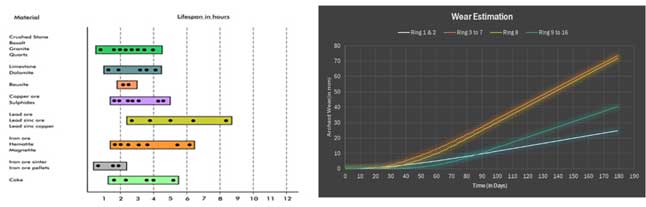

- SimLife - Predicts Life of the panels (Abrasive Wear & Impact Wear)

- SimStrength - Calculate Strength

The software packages used are:

- Ansys

- EDEM

- Autodesk Design Suite

SimEff -

To calculate the screening efficiency by proper selection of Aperture’s shape, size, and position. Also determining its Open Area Requirement.

Our proprietary and high-end software developed with our 45+ years of rich experience and database of over 900 cases help in accurately predicting the screening efficiency and ways to improve the screening efficiency.

SimLife -

To predict the expected life of the screen decks.

It takes into account ore characteristics, operating parameters with Tega’s experience on wear properties to predict the life of the panels.

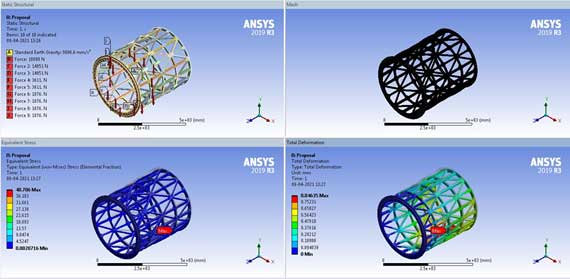

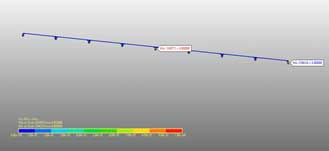

SimStrength -

To calculate the strength of panels.

Tega’s high-end software along with Ansys helps to accurately design and validate the panels in terms of strength.

3D Modelling

Modelling of each component at the pre-manufacturing stage to ensure perfect fitting of Tega Screen Decks.

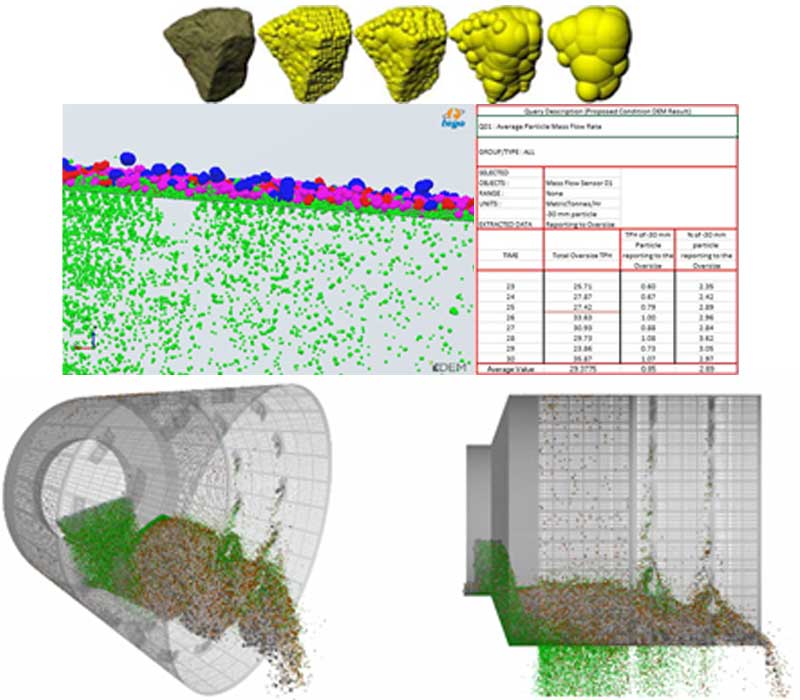

Material Flow Analysis

The behaviour or movement of the particle over screen or trommel is simulated using our DEM software to accurately model the existing and proposed flow pattern.

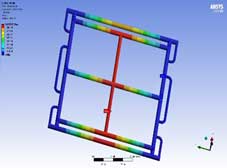

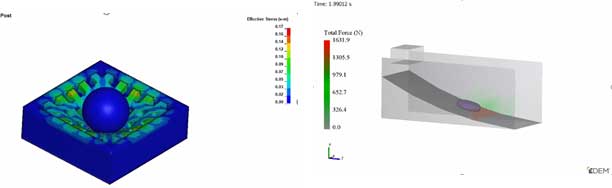

Impact load Analysis

The feed zone is highly subjected to the impact loads and our advanced FEA simulations help in designing under panels for the specific application.

Dynamic simulation

The panels in a dynamic environment are simulated to determine the fatigue life, fixing strength, etc.

Installation Supervision

- When requested, we provide our customers with General Arrangement drawings for the Screen Media.

- Supervision of installation of our screen media and modifications of bucker up frame is part of our value-added service.

Wear Measurements

- Wear measurements are a source of invaluable information as it helps us in the estimation of spares. A Wear Measurement Report is submitted to all our customers after every maintenance shutdown. This assists our customers in planning their inventories.

- Monthly Stock & Inventory reports for our clients to help them in better planning for maintenance.