Products

DynaWear®

Ideal for all Ball mills, Rod Mills, Batch Mills, Scrubbers, Mixing Drums, FGD mills etc.

Rubber Mill Liner for Optimal Wear

Tega Mill Linings provide optimal grinding solutions in major mineral processing plants all over the world. The Tega DynaWear® rubber lining system is the preferred lining system for secondary ball mills, regrind mills and scrubbers.

DynaWear® rubber mill linings are individually designed for your particular working conditions and goals, with a variety of profiles and materials available for specific applications. Secondary and Regrind applications are ideal for DynaWear®, ensuring optimised mill liner life, grinding efficiency and capacity, delivering maximum cost benefit to our clients.

DynaWear® is ideal for mills operating with highly acidic slurry and sets the standard of comparison for grinding performance and lining economy that has been successfully used in a wide range of primary, secondary and tertiary grinding mills, batch mills and scrubbers.

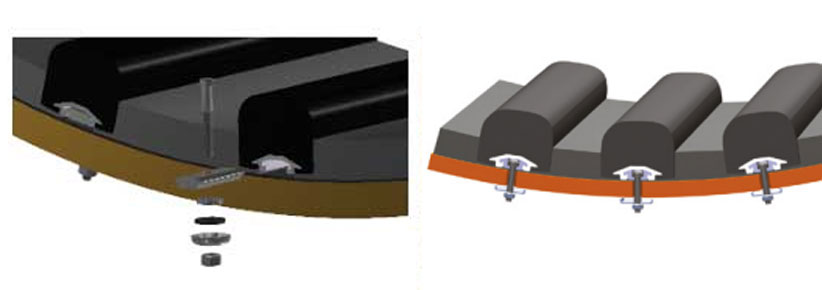

DynaWear® Fastening System

DynaWear® reinforced lifters have an integrated aluminium track to accommodate the fixing clamp. Non-reinforced Tega Lifter Bars are installed with detachable steel clamps which can slide inside the groove on the lifter base and are then bolted to the mill shell. The lining bolt attachment system are also available with different grades of steel for very high or low pH-values.

DynaWear® Advantages

- Superior compoundsLonger liner life/less liner cost per tonne

- Reduced installation time compared to steelIncreased mill availability

- Reduction in noise levelsReduced overall noise pollution

- Leak proof fastening systemBetter protection of mill against corrosion & washing

- Less liner weight compared to steelLonger life of rotating parts. Liner is safer to handle and install

- Scheduled Tega liner monitoring programPrediction of liner life and change out dates

APPLICATION AREAS

- AG Mills

- Ball Mills

- Scrubbers

- Batch Mills

- Lime Slaker Mills

- Mixing Drums

- Slag Mills

- Pebble Mills

- FGD Mills

- Regrind Mills

- Continuous Mills

Why choose us?

Why Choose Us 01

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 02

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 03

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 04

Sed quia non numquam eius modi tempora incidunt ut labore.

Tega DynaSteel

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.

Advantages of Tega DynaSteel

- Increase Mill availability to process more ore

- Increase Mill operation time as a result of faster relining

- Increase Life as per plant requirement

- Increase ball charge volume due to decrease in liner weight

- Lower Maintenance cost

- Lower Energy expenses

- Less personnel required for installation

- Faster reline due to lesser number of fixings for liner installation

- Do away with unplanned shut-down

- Better Liner profile stability throughout the campaign

- Installation from outside

- No chance of any fatal accident

- No use of oxy-flame inside the mill at the time of dismantling the liners

- Lower CEE required, enabling reduction in carbon footprint

- Reduces the environmental contamination by eliminating oxy-flame cutting

Tega DynaWear

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.

Advantages of Tega DynaWear

Tega DynaPulp

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.