Products

OptiNext

Tega OptiNext© range comprises the following products:

- OptiNext© Rubber Rapido

- OptiNext© PU Rapido

- OptiNext© Rubber Modular Pin & Lug

- OptiNext© PU Modular Pin & Lug

- OptiNext© Rubber Modular Button Type

- OptiNext© PU Modular Button Type

- OptiNext© PU Birdbeak

- OptiNext© PU Button type half

- OptiNext© PU V type panel

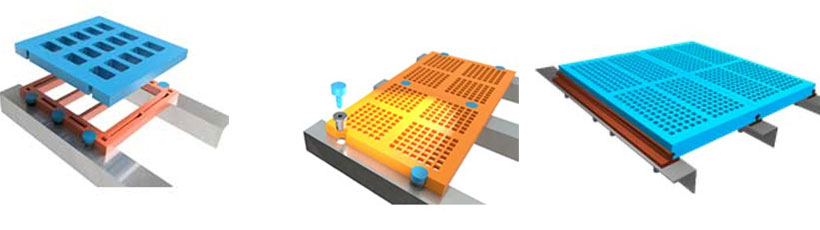

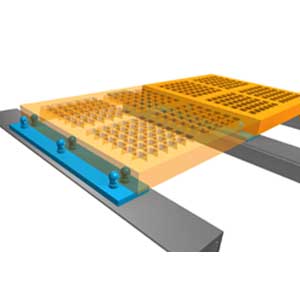

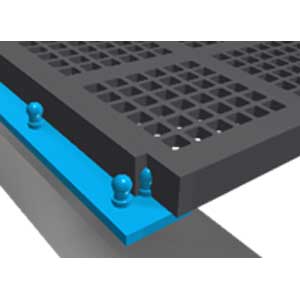

OptiNext© Rubber Rapido & OptiNext© PU Rapido

Problems it covers: Clogging and low efficiency

Providing the perfect solution: Tega is the market leader when it comes to providing efficient, resilient and smart screening solutions. To pursue its philosophy of improving screening efficiency, optimizing life and reducing downtime, we have developed a revolutionary patented product called Rapido. The panels are made in two halves where the top half is replaced when worn-out, leaving the bottom part fixed on the bucker-up frame, resulting in improving the uptime of the screen machine and additional secondary vibration. This leads to the reduction in clogging.

Tega Modular Panels provide simple fixing options that prevent time-consuming and difficult installation with a wide range of applications in both wet and dry applications. The aperture and fixing option can be selected based on your specific requirement. The panels are designed to optimize efficiency and life without compromising on the installation time.

Product Advantages

| Conventional Screen Panels | Rapido |

| Whenever the panels are to be replaced the new panels have to be aligned on the bucker-up frame thereby increasing the downtime of the screen | Since the bottom part remains fixed with the bucker-up frame, no alignment is required. The Top panels can be fixed in less than 50% of the time, resulting in a saving of 20 Times the cost of the deck |

| The integral nature of the screen panels adds to the overall weight triggering handling inconveniences. | Separate detachable section increases handling convenience, as one has to handle lighter parts at a time. |

| At the time of replacement, the customer has to throw away the remaining panels, which is greater than 60% of the original panels thereby creating more industrial waste. | Only the top screening part has to be replaced thus substantially reducing the industrial waste, resulting in the reduction of carbon footprint, which amounts to 800 gms of CO2 Emission per panel. |

| For any change of freed characteristic, the entire set of panels has to be thrown off and has to be replaced by panels with new apertures. | In similar cases, the top part can be replaced with another top part of a different aperture thus reducing the downtime and increasing the efficiency of the screen. |

Product Application Details

| Application | Predominantly for dry & wet Application for Clogging Removal and faster installation & removal |

| Size | 1ft x 1ft, 1ft x 2ft panels |

| Fixing options | Pin & Lug & Button Type Fixing |

| Material Options | Top Part : Rubber (40 to 73 Shore A ), Polyurethane ( 85 to 95 Shores A) Bottom Part : Steel Reinforced Polyurethane ( 85 to 95 Shores A) |

| Aperture Options | Rubber: Square (5mm – 40 mm), Slotted (5 mm to 65 mm), Zigzag, Round, Teardrop (Customized size available on demand) Polyurethane: Square (2mm – 40 mm), Slotted (0.5 mm to 40 mm), Zigzag, Round, Teardrop (Customized size available on demand) |

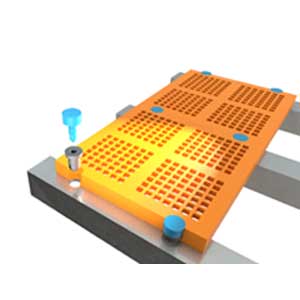

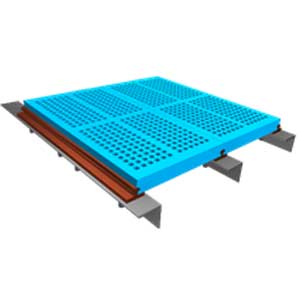

OptiNext© Rubber Modular Pin & Lug & OptiNext© PU Modular Pin & Lug

Problems it covers: Low efficiency and difficulty fixing

Providing the perfect solution

Product Advantages

- Optimum life and efficiency to suit your requirement.

- Small Panels, light in weight

- Easy to Handle

- Individual panels that are very strong and steady and hence does not sag during operation

- Can be easily replaced in case of localized wear.

- Snap-on type fixing helps in faster change over.

- Since there are no locking strips for fixing the panels, the percentage of the open area of our panels will be higher than conventional screen decks.

- Low replacement cost as large panels is split into numbers of small modular panels

Product Application Details

| Application | Wet & dry applications |

| Size | 1ft x 1ft, 1ft x 2ft panels |

| Fixing options | Pin & Lug, Button Type, Half button type, V- Type (Others type available on demand) |

| Material Options | Polyurethane ( 85 to 95 Shores A) Rubber (40 to 73 Shores A) |

| Aperture Options | Polyurethane: Square (2 mm – 50 mm), Slotted (0.3 mm to 50 mm), Zigzag, Round, Teardrop (others based on demand) Rubber: Square (5 mm – 110 mm), Slotted (5 mm to 110 mm), Zigzag, Round, Teardrop (others based on demand) |

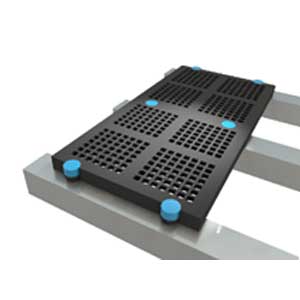

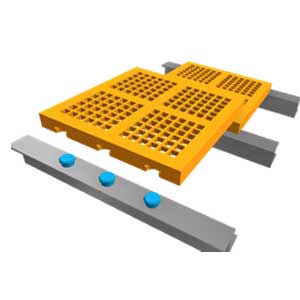

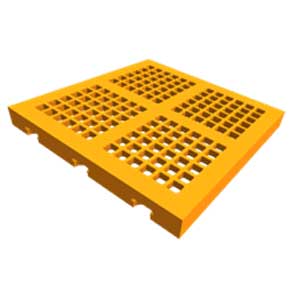

OptiNext© Rubber Modular Button Type & OptiNext© PU Modular Button Type

Problems it covers: Low efficiency and difficulty fixing

Providing the perfect solution

Product Advantages

- Optimum life and efficiency to suit your requirement.

- Small Panels, light in weight

- Easy to Handle

- Individual panels that are very strong and steady and hence does not sag during operation

- Can be easily replaced in case of localized wear.

- Snap-on type fixing helps in faster change over.

- Since there are no locking strips for fixing the panels, the percentage of the open area of our panels will be higher than conventional screen decks.

- Low replacement cost as large panels is split into numbers of small modular panels

Product Application Details

| Application | Wet & dry applications |

| Size | 1ft x 1ft, 1ft x 2ft panels |

| Fixing options | Pin & Lug, Button Type, Half button type, V- Type (Others type available on demand) |

| Material Options | Polyurethane ( 85 to 95 Shores A) Rubber (40 to 73 Shores A) |

| Aperture Options | Polyurethane: Square (2 mm – 50 mm), Slotted (0.3 mm to 50 mm), Zigzag, Round, Teardrop (others based on demand) Rubber: Square (5 mm – 110 mm), Slotted (5 mm to 110 mm), Zigzag, Round, Teardrop (others based on demand) |

OptiNext© PU Birdbeak

Problems it covers: Slurry penetration and higher downtime

Providing the perfect solution:Tega Modular Birdbeak panels provide highly flexible fixing options that help safeguard the bucker-up frame in wet or dewatering applications. The aperture can be selected to suit your requirement. The bottom adapter bar which helps to secure the panels to the frame additionally prevents the slurry inclusion to the bucker-up frame resulting in lower machine maintenance and improved life. The special reinforcement designs permit additional flexibility for improving efficiency.

Product Advantages

- Flexible & Very easy to replace

- Prevent slurry from damaging the screen frame

- Snap-on type fixing helps in faster change over.

- Better cost per ton compared to the existing one.

- Fits in the existing BU frame. No modification is required.

- No compromise with the life & flexibility of manufacturing & design changes.

Product Application Details

| Application | Wet applications |

| Size | 1ft x 2ft panels |

| Fixing options | Birdbeak Adapter fixing |

| Material Options | Polyurethane ( 85 to 95 Shores A) |

| Aperture Options | Polyurethane: Square (2 mm – 30 mm), Slotted (0.3 mm to 30 mm), Teardrop (others based on demand) |

OptiNext© PU Button type half

Problems it covers:Low efficiency and difficulty fixing

Providing the perfect solution:

Product Advantages

- Optimum life and efficiency to suit your requirement.

- Small Panels, light in weight

- Easy to Handle

- Individual panels that are very strong and steady and hence does not sag during operation

- Can be easily replaced in case of localized wear.

- Snap-on type fixing helps in faster change over.

- Since there are no locking strips for fixing the panels, the percentage of the open area of our panels will be higher than conventional screen decks.

- Low replacement cost as large panels is split into numbers of small modular panels

Product Application Details

| Application | Wet & dry applications |

| Size | 1ft x 1ft, 1ft x 2ft panels |

| Fixing options | Pin & Lug, Button Type, Half button type, V- Type (Others type available on demand) |

| Material Options | Polyurethane ( 85 to 95 Shores A) Rubber (40 to 73 Shores A) |

| Aperture Options | Polyurethane: Square (2 mm – 50 mm), Slotted (0.3 mm to 50 mm), Zigzag, Round, Teardrop (others based on demand) Rubber: Square (5 mm – 110 mm), Slotted (5 mm to 110 mm), Zigzag, Round, Teardrop (others based on demand)\ |

Why choose us?

Why Choose Us 01

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 02

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 03

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 04

Sed quia non numquam eius modi tempora incidunt ut labore.

Tega DynaSteel

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.

Advantages of Tega DynaSteel

- Increase Mill availability to process more ore

- Increase Mill operation time as a result of faster relining

- Increase Life as per plant requirement

- Increase ball charge volume due to decrease in liner weight

- Lower Maintenance cost

- Lower Energy expenses

- Less personnel required for installation

- Faster reline due to lesser number of fixings for liner installation

- Do away with unplanned shut-down

- Better Liner profile stability throughout the campaign

- Installation from outside

- No chance of any fatal accident

- No use of oxy-flame inside the mill at the time of dismantling the liners

- Lower CEE required, enabling reduction in carbon footprint

- Reduces the environmental contamination by eliminating oxy-flame cutting

Tega DynaWear

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.

Advantages of Tega DynaWear

Tega DynaPulp

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.