Products

OptiSlim

Tega OptiSlim© range comprises following products:

- Optislim© PU Flipflo Leg Type

- Optislim© PU Flipflo Non leg type

- Optislim© PU Flexi for screen

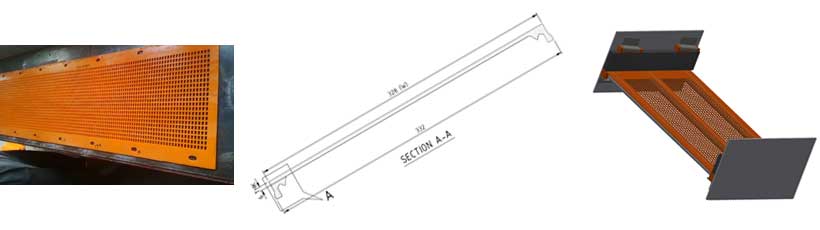

Optislim© PU Flipflo Leg Type & Optislim© PU Flipflo Non leg type

Problems it covers:Areas with high moisture content where conventional panels lose efficacy

Providing the perfect solution:Tega Flipflo panels offer a higher open area to delivers optimum efficiency and life in highly moist environments. These panels are specially designed for Flipflo screens to endure high vibrational loads and ensure the required fatigue life.

Product Advantages

- Flexible & very easy to replace

- High Wear life of the panels

- Used in application to combat high clogging.

- Increase the G- Value of the particles due to secondary vibration resulting in a higher probability of separation

- Higher flexibility in apertures

- Customize Aperture based on your requirement

Product Application Details

| Application | Predominantly for applications in flip flop screens which operate in highly moist ores. |

| Size | Width - Can be adjusted according to the customer screen width. Length – 246 to 342 (others based on demand) Thickness – 4 to 8 mm (others based on demand) |

| Fixing options | Leg type- Wedge fixing Non-leg type- Bolt fixing |

| Material Options | Polyurethane : 85 to 95 Shore A |

| Aperture Options | Square (3mm – 50 mm), Slotted (3 mm to 50 mm), Options of customization available |

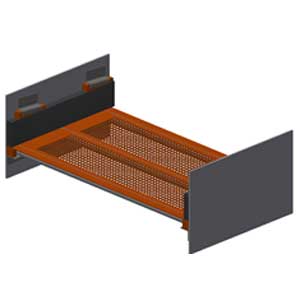

Optislim© PU Flexi for screen

Problems it covers:Clogging and low efficiency

Problems it covers:

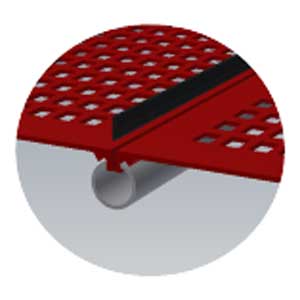

- To persue our philosophy of improving screening efficiency, optimizing life & reducing downtime, and keeping in mind the safety of the people we have come up with a product “FLEXI” that would be very easy to handle and would work at very high efficiency even in extremely high moisture content environment with its highly flexible nature resulting in secondary vibrations ensuring blind free operation.

- Tega Flexi panels can be installed on any screen with minor modifications and are equipped with a very high open area

'FLEXI' Working Principle

- Energy transmitted ∞ Amplitude 2

- This screen deck is generally 8-10mm thick.

- Lower thickness permits lesser rigidity when compared with the wire mesh screen. In fact, the amplitude of vibration for the FLEXI screen is higher than both wire-mesh and conventional PU screens

- The higher energy that is transmitted through the panel induces a self-cleaning property within the panel.

Product Advantages

- High Open Area: All Tega Flexi panels are customizable according to the application ensuring a high open area for every application.

- Ease of Installation: Tega Flexi Panels are easy to install on conventional screens and due to the absence of any reinforcements, they are extremely easy to maneuver and install.

- No Clogging and Blinding: Lower thickness permits lesser rigidity when compared with the wire mesh screen. In fact, the amplitude of vibration for the FLEXI screen is higher than both wire-mesh and conventional PU screen. The higher energy transmitted via the panel induces a self-cleaning property within the panel.

- Services: We provide various value-added services like the maintenance of the structure, wear measurements as well as performance validation.

Product Application Details

| Application | Predominantly for applications with high moisture content along with a lot of fines resulting in high blinding in screens |

| Size | Width - Customizable according to the customer screen width. Length – 246 to 342 (others based on demand) Thickness – 4 to 8 mm (others based on demand) |

| Fixing options | Pipe & Wedge Fixing or Adapter bar fixing Bolt Down Fixing |

| Material Options | Polyurethane : 85 to 95 Shore A |

| Aperture Options | Square (3mm – 50 mm), Slotted (3 mm to 20 mm), Options of customization available |

Why choose us?

Why Choose Us 01

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 02

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 03

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 04

Sed quia non numquam eius modi tempora incidunt ut labore.

Tega DynaSteel

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.

Advantages of Tega DynaSteel

- Increase Mill availability to process more ore

- Increase Mill operation time as a result of faster relining

- Increase Life as per plant requirement

- Increase ball charge volume due to decrease in liner weight

- Lower Maintenance cost

- Lower Energy expenses

- Less personnel required for installation

- Faster reline due to lesser number of fixings for liner installation

- Do away with unplanned shut-down

- Better Liner profile stability throughout the campaign

- Installation from outside

- No chance of any fatal accident

- No use of oxy-flame inside the mill at the time of dismantling the liners

- Lower CEE required, enabling reduction in carbon footprint

- Reduces the environmental contamination by eliminating oxy-flame cutting

Tega DynaWear

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.

Advantages of Tega DynaWear

Tega DynaPulp

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.