Products

OptiTrommel

Tega OptiSlim© range comprises following products:

- OptiTrommel© NPS

- OptiTrommel© RPS

- OptiTrommel© Scat Return Mechanism

- OptiTrommel© Overflow Discharge System

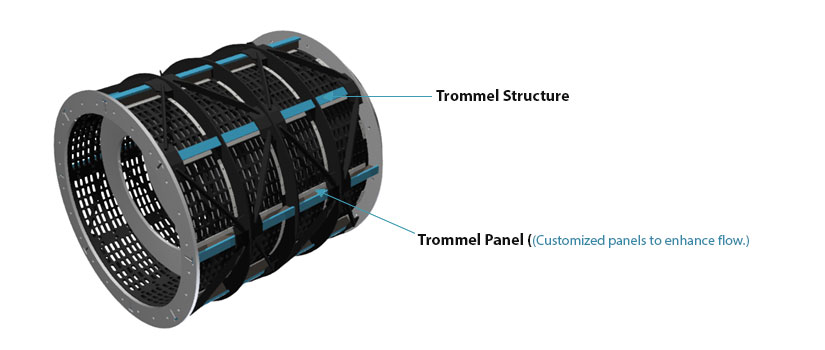

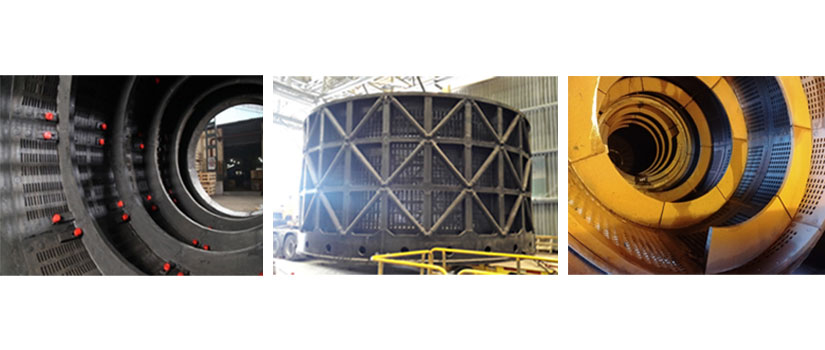

OptiTrommel© Structure

Tega is the market leader in providing a wide range of Trommel for heavy and light duty applications. The structures come with rubber or polyurethane screen panels, spirals, connecting pieces, and end flanges. The structures are custom designed for higher efficiency, capacity and wear life.

Trommel Panel

Tega Trommel panels have wide range of options to suit the specific customer requirement. The panels are specifically designed with detailed analysis of the operating parameters, feed distribution, material characteristics and environmental factors to provide the optimum performance in terms of life and efficiency. The fixing options are provided with panels to ensure lower downtime and efficient operation, resulting in lower maintenance time.

Why Tega Opti-Trommel?

- Customized Trommels: All Tega Trommels are customised according to the applications.

- Low cost per ton: All Tega Trommels pass through the Finite Element Test and Discrete Element test to arrive at optimised design.

- Modular Screen panel options: The modular screen panels allow the change over time to be minimal and allow the customer the flexibility to try with different apertures.

- Services: Tega provides various value added services consisting of the relining of structures, replacement of panels, finding exact time of replacement with online wear measurements etc.

- Optimum Sizing: Tega Structures are optimally sized to provide enhanced capacity with minimal space.

- Fixing Option: Tega provides a wide range of fixing options to suit specific customer requirement.

- Panels & Aperture Selection:Customized panels are designed with optimum open area to ensure optimum efficiency and longevity of the panels

Solution Customization

Trommel Application Details

| Application | SAG Mill, Ball Mill, AG Mill, Scrubbers. |

| Size | Diameter: 2 ft. to 24 ft. Length: 2 ft. to 30 ft. |

| Aperture Options | Square, Slotted (Customize aperture available on demand) |

| Panel Option | Opti-Prime, Opti-Next |

| Application Area | Iron Ore processing plant, Copper & Gold Ore processing plants, aggregate industries and other mineral processing and mining plants |

| Other Available Features |

|

TEGA TROMMEL SERVICES

- Troubleshooting: Enhancing of Trommel efficiency, increasing panel life and the uptime

- Site services: Installation & Supervision.

- Wear measurement: Scheduling wear measurement for planned maintenance, shutdown and optimizing inventory

- Refurbishing Refurbishing of structure as well as replacement of panels and spirals

OptiTrommel© NPS

Problems it covers: Higher compatibility with wide usage for heavy as well as light duty applications

Providing the perfect solution: Tega is the market leader in providing a wide range of Trommels for usage in heavy and light-duty applications. The structure comes with rubber or polyurethane screen panels, spirals, connecting pieces,and end flanges. Our Trommels are custom designed and FEA validated to optimize the sizes, capacity, wear life and ensure structural strength during operations.

OptiTrommel© RPS

Problems it covers: Trommel size limiting the overall capacity

Providing the perfect solution: With OptiTrommel© RPS, capacity can be increased with the same Trommel length or similar capacity can be achieved with a shorter Trommel length.

Benfits- Optimized structural design

- Optimized slurry retention time

- Increased capacity with same Trommel length

- Existing Capacity with shorter Trommel length

OptiTrommel© Scat Return Mechanism

Problems it covers: Unwanted scat in the overflow

Providing the perfect solution: OptiTrommel© Scat Return Mechanism helps to selectively remove the scat from reporting to the overflow of the Trommel. The special scooping arrangement is provided at the discharge end to capture the unwanted scat and to send them back to the mill for reuse.

Benfits- Selective removal of the unwanted scat from the overflow

- Reuse of the scat

OptiTrommel© Overflow Discharge System

Problems it covers: Overflow of unwanted slurry

Providing the perfect solution: OptiTrommel© Overflow Discharge System helps to improve the retention time with a recess or buffer. This detachable system is attached at the discharge end of the Trommel. It helps to lift the oversized material selectively from the slurry. It thus prevents the overflow of slurry.

Benfits- Optimized Structural design.

- Detachable recess or buffer system to increase the retention time of the slurry

- Selective lifting of the oversize material

- Preventing the issue of slurry overflow

Why choose us?

Why Choose Us 01

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 02

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 03

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 04

Sed quia non numquam eius modi tempora incidunt ut labore.

Tega DynaSteel

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.

Advantages of Tega DynaSteel

- Increase Mill availability to process more ore

- Increase Mill operation time as a result of faster relining

- Increase Life as per plant requirement

- Increase ball charge volume due to decrease in liner weight

- Lower Maintenance cost

- Lower Energy expenses

- Less personnel required for installation

- Faster reline due to lesser number of fixings for liner installation

- Do away with unplanned shut-down

- Better Liner profile stability throughout the campaign

- Installation from outside

- No chance of any fatal accident

- No use of oxy-flame inside the mill at the time of dismantling the liners

- Lower CEE required, enabling reduction in carbon footprint

- Reduces the environmental contamination by eliminating oxy-flame cutting

Tega DynaWear

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.

Advantages of Tega DynaWear

Tega DynaPulp

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.