Products

OptiPrime

Tega OptiPrime© range comprises the following products:

- OptiPrime© Rubber Panel Cord

- OptiPrime© Rubber Panel Cord with rider bar

- OptiPrime© Rubber Bolt Down

- OptiPrime© Rubber Cross Tension

- OptiPrime© PU Cross Tension

- OptiPrime© PU Bolt Down

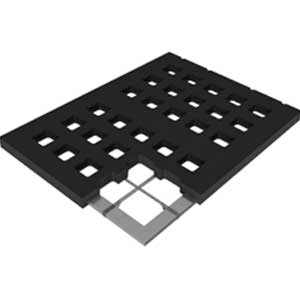

OptiPrime© Rubber Panel Cord

Problems it covers: Larger lumps with huge impact that results in lower panel life and efficiency

Providing the perfect solution: Tega Rubber Panel Cords are designed to impart strength without compromising on flexibility. The special fiber-reinforced design provides enough flexibility to prevent clogging in the apertures.

Product advantages

- Reduced clogging in Scalping/Primary Application

- Lower Cost per ton

- Robust Design for very heavy-duty applications involving larger lumps.

- Reduces Noise

- High Wear Life or Long-Lasting design

Product Details

| Application | Primary Circuit in both wet & dry Application |

| Size | 2 ft. x 2 ft. to 4 ft. x 4 ft. (Customized size available on demand) |

| Fixing options | Bolt-down (Customized fixing available on demand) |

| Material Options | Rubber( 40 to 73 Shores A) |

| Aperture Options | Square (10 mm to 100 mm), Slotted (10 mm to 100 mm) (Customized size available on demand) |

OptiPrime© Rubber Panel Cord with rider bar

Problems it covers: Larger lumps with huge impact that results in lower panel life and efficiency

Providing the perfect solution: The Tega Rubber Panel Cords are designed to impart strength without compromising on flexibility. The special fiber-reinforced design provides enough flexibility to prevent clogging in the apertures. The rider bars helps in effective stratification and better removal of fines.

Product Advantages

- Lower cost per ton

- Reduced clogging in scalping/primary applications

- Rider bars helps in better stratification by the segregation of large lumps that ride on the bars and separate

- Improved life by 30-40%, achieved by extra material of rider bar

- Robust design for very heavy-duty applications

- Reduces noise

- High wear life or long lasting design

Product Details

| Application | Primary Circuit in both wet & dry Application |

| Size | 2 ft. x 2 ft. to 4 ft. x 4 ft.(Customized size available on demand) |

| Fixing options | Bolt-down (Customized fixing available on demand) |

| Material Options | Rubber( 40 to 65 Shores A) |

| Aperture Options | Square (10 mm to 100 mm), Slotted (10 mm to 100 mm) (Customized size available on demand) |

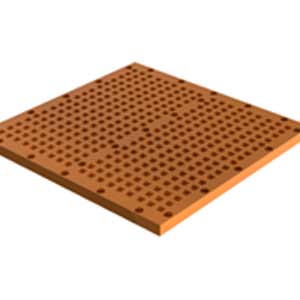

OptiPrime© Rubber Bolt Down & OptiPrime© PU Bolt Down

Problems it covers: Larger lumps with huge impact that results in lower panel life and efficiency

Providing the perfect solution: Tega Bolt Down Panels are of robust design to handle large lump size for optimum life and efficiency. These panels sustain the heavier load and provide a long lifespan. PU variant is applicable in areas where abrasive ore with a low lump size is found. These panels can handle comparatively higher flow rates.

Product Advantages

- Lower cost per ton

- The product can be customized as per application requirements.

- Mostly used in Scalping/Primary Application to handle heavy loads

- For Apertures above 20 mm, rider bars design are provided for

- Better Stratification

- Segregation of Large lumps that ride on the bars and separate out

- Improved life by 30-40%, by extra material of rider bar.

- Robust Design for very heavy-duty applications

- Reduces Noise

- High Wear Life or Long-Lasting design

Product Details

| Application | Primary, Secondary & Tertiary Circuits in both wet & dry Application |

| Size | 2 ft. x 2 ft. to 4 ft. x 4 ft.(Customized size available on demand) |

| Fixing options | Bolt-down |

| Material Options | Rubber( 40 to 73 Shores A), Polyurethane ( 85 to 95 Shore A) |

| Aperture Options | Rubber: Square (10 mm to 100 mm), Slotted (10 mm to 100 mm), Round (Customized size available on demand) Polyurethane: Square ( 2 mm to 50 mm), Slotted (0.3 mm to 50 mm), Round (Customized size available on demand) |

OptiPrime© Rubber Cross Tension & OptiPrime© PU Cross Tension

Problems it covers: Larger lumps in sticky ore regions that make screening challenging

Providing the perfect solution: Tega Cross-tension Panels have been designed to replace the existing wire mesh technology and provide a better cost per ton with the existing fixing arrangements. The reinforced steel cords provide enough tension and strength without compromising on the flexibility. These panels are highly effective in applications where high-intensity clogging is a serious issue.

Product Advantages

- Lightweight panel

- Lower cost per ton

- No change in the bucker-up frame required

- Higher open area contributes to more effective screening.

- Reduced clogging due to higher secondary vibration and low thickness.

- Reduction in Noise during the operation

Product Details

| Application | Primary Circuit in both wet & dry Application |

| Size | 2 ft. x 2 ft. to 4 ft. x 4 ft.(Customized size available on demand) |

| Fixing options | Cross- Tension (Customized fixing available on demand) |

| Material Options | Rubber( 40 to 73 Shores A), Polyurethane ( 85 to 95 Shore A) |

| Aperture Options | Rubber: Square (10 mm to 100 mm), Slotted (10 mm to 100 mm), Round (Customized size available on demand) Polyurethane: Square ( 2 mm to 50 mm), Slotted (0.3 mm to 50 mm), Round (Customized size available on demand) |

Why choose us?

Why Choose Us 01

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 02

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 03

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 04

Sed quia non numquam eius modi tempora incidunt ut labore.

Tega DynaSteel

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.

Advantages of Tega DynaSteel

- Increase Mill availability to process more ore

- Increase Mill operation time as a result of faster relining

- Increase Life as per plant requirement

- Increase ball charge volume due to decrease in liner weight

- Lower Maintenance cost

- Lower Energy expenses

- Less personnel required for installation

- Faster reline due to lesser number of fixings for liner installation

- Do away with unplanned shut-down

- Better Liner profile stability throughout the campaign

- Installation from outside

- No chance of any fatal accident

- No use of oxy-flame inside the mill at the time of dismantling the liners

- Lower CEE required, enabling reduction in carbon footprint

- Reduces the environmental contamination by eliminating oxy-flame cutting

Tega DynaWear

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.

Advantages of Tega DynaWear

Tega DynaPulp

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.