Products

Aggression Composite Liner

High impact load and wear for heavy-duty applications

Providing the perfect solution: Our Composite Liners are designed to handle bulk material ranging upto 400 mm in size. The high hard steel embedded in the rubber matrix gives excellent resistance to wear in addition to the absorption of impact energy. This provides the liner with an extended working life that is 3-4 times more than liners made of either rubber or steel.

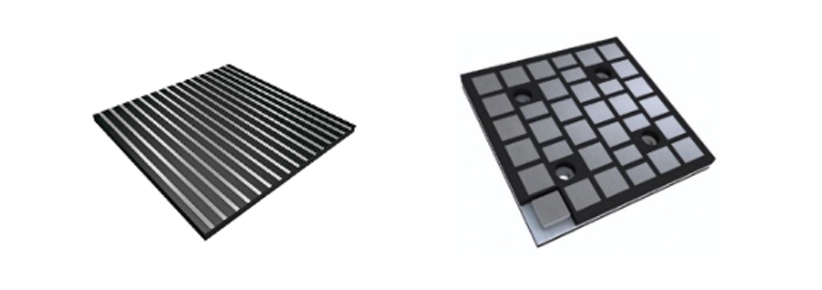

Aggression SB-PM

This range of composite liners with high hard steel ribs embedded inside the rubber matrix provides great impact resistance, resists abrasion and ensures high wear life. It is one of the robust and most efficient liners to handle both impact and abrasive lumpy ores.

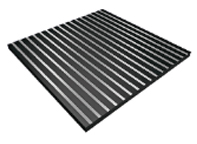

Aggression Mosaic

This new generation liner, having special high hard steel placed in rubber matrix, offers excellent resistance to impact and wear. It also promotes longevity.

Aggression PU-PM

This liner consists of high hard steel ribs embedded inside a polymer matrix. It provides excellent impact and abrasion resistance, besides improving the flow.

Why choose us?

Why Choose Us 01

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 02

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 03

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 04

Sed quia non numquam eius modi tempora incidunt ut labore.

Tega DynaSteel

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.

Advantages of Tega DynaSteel

- Increase Mill availability to process more ore

- Increase Mill operation time as a result of faster relining

- Increase Life as per plant requirement

- Increase ball charge volume due to decrease in liner weight

- Lower Maintenance cost

- Lower Energy expenses

- Less personnel required for installation

- Faster reline due to lesser number of fixings for liner installation

- Do away with unplanned shut-down

- Better Liner profile stability throughout the campaign

- Installation from outside

- No chance of any fatal accident

- No use of oxy-flame inside the mill at the time of dismantling the liners

- Lower CEE required, enabling reduction in carbon footprint

- Reduces the environmental contamination by eliminating oxy-flame cutting

Tega DynaWear

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.

Advantages of Tega DynaWear

Tega DynaPulp

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.