Tega has been a leader in the design and supply of hydrocyclones for the mining and mineral processing industry for over two decades now. We offer tailor-made products boasting of robust designs for optimized performance and longer service life. Our hydrocyclones are made for wet classification with higher capacity and sharper cut points.

Problems it covers: Finding the right equipment for fine size separation

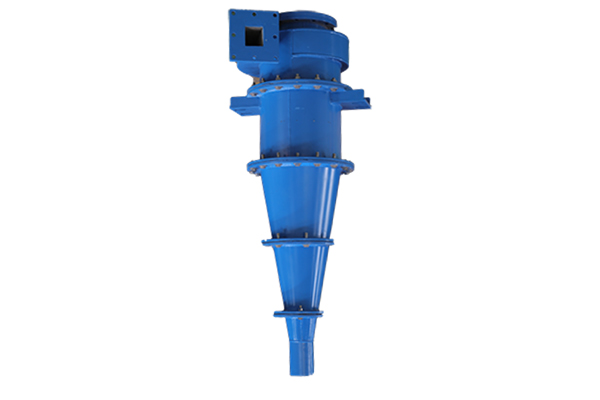

Providing the perfect solution:The Tega Tornado range of hydrocyclones are known for an innovative product portfolio, delivering comprehensive solutions in classification, beneficiation, de-sliming, de-gritting and de-watering applications associated with mineral processing industries.

Configuration

- Recovery from classifier slimes

- Recovery from cyclone overflow (extreme slimes)

- Beneficiation of feed to pellet plant

- Pre-concentration of feed to magnetic separator

- Recovery of iron from old tailings

- Hydrate classification

- Spent liquor/Weak soda recovery

- Sand separation

- Beneficiation of coal fines

- Thickening of fine coal slurry

- Desliming/Classification

- Classification in closed circuit grinding

- Free gold recovery from primary cyclone underflow

- Recovery of gold from plant tailing

- Backfill sand preparation

- Reduction of carbonaceous materials

- Beneficiation of chromite ore

- Dewatering/Desliming

- Desliming/Dewatering

- Degritting/Recovery of fine clay

Iron Ore Industry

Alumina Refinery

Coal Washery

Gold Ore Processing Plants

Chromite Ore Beneficiation Plants

Beach Sand

Clay Industry

Involute entry

- Reduce turbulence

- Improves efficiency

- Reduces wear

- Finer cut points

Modular Design

- Easy maintenance

- Reduced operational cost

- Flexibility in up-gradation

Different Cone Angles

- Wide range of cut points

- Optimized selection

- Optimized performance

HDPE Overflow Pipe

- Light weight

- Easy installation

- Less maintenance time

- Reduced load on the structure

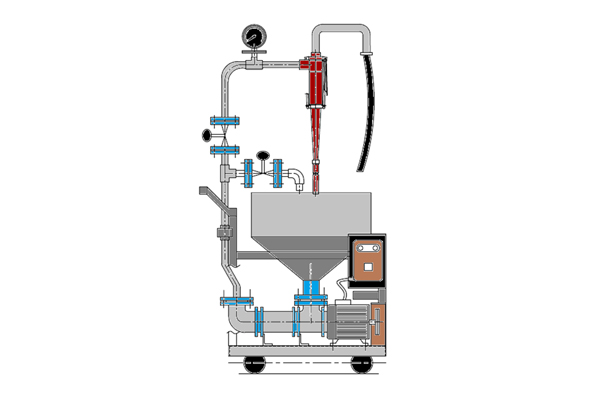

Innovative cluster design

- Compact and efficient design

- Multiple segregated outlets

- Easy operation

| CYCLONE SIZE (INCH) | Body diameter (mm) | Inlet Pipe Size (mm) | Overflow Pipe Size (mm) | Material of Construction | Special Liner |

|---|---|---|---|---|---|

| 2 | 50 | 25 | 40 | Polyurethane | - |

| 3 | 75 | 25 | 50 | Polyurethane | - |

| 4 | 100 | 50 | 80 | Polyurethane | - |

| 5 | 125 | 50 | 80 | Polyurethane | - |

| 6 | 150 | 80 | 100 | Polyurethane / Rubber Liner in steel housing | NbSiC Apex & VF |

| 8 | 200 | 100 | 150 | Polyurethane | NbSiC Apex & VF |

| 10 | 250 | 100 | 150 | Polyurethane / Rubber Liner in steel housing | NbSiC |

| 11 | 275 | 100 | 150 | Polyurethane | NbSiC |

| 15 | 380 | 150 | 200 | Rubber Liner in steel housing | NbSiC |

| 20 | 500 | 200 | 250 | Rubber Liner in steel housing | NbSiC |

| 26 | 660 | 250 | 300 | Rubber Liner in steel housing | NbSiC |

Our top-notch expertise in Engineering can be summarized as below:

- High end advanced simulation software for selection and design of hydrocyclone such as JK SimMet, Symcyclone which are extensively tested and accepted software in the field of Mineral processing. Apart from the above, we use internally developed and industrially validated GEM-Cyclone software for selection and design of the Hydrocyclone.

- Extensive in-house R&D facility.

- Superior hydraulic designs and wear resistant materials.

- Provision of Special grade liners for highly abrasive applications.

- Highly qualified & experienced engineering professionals to deal with the technical aspects & product design

- State of the art manufacturing facility.

TEGA Industries Limited provides the best before and after sales services possible, through our in-house engineering personnel, independent consultants and technical product and application specialists within the group. Emphasis is laid on finding cost-effective solutions to technical problems and adopting a professional approach for each application.

Pre-sales service

- A thorough study of the application for detailed operational conditions.

- Evaluation through high-end advanced simulation software for selection and design of hydrocyclones.

- Trouble shooting such as defining areas where improvement of cost-effectiveness is possible, as well as outlining the technical solution and economical evaluation.

After-sales service

- Supervision of installation and commissioning of TEGA products, supervised by our experienced in-house engineering team.

- Trouble-shooting and revision of designs.

- Monitoring the performance and wear rate of individual sections.