Products

DynaSteel®

Ideal for SAG mill (Diameter below 34 ft.) and Ball Mill (Diameter between 15ft and 18 ft.)

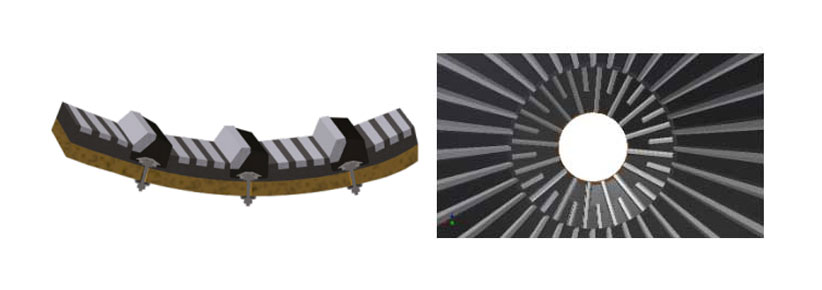

DynaSteel® Composite Mill Liners

DynaSteel® is tailor-made for each mill in question, to provide a maximum protection against wear, prolonging the mill operation time.

- DynaSteel® uses different alloys and rubber compounds to engineer a perfect blend for aggressive grinding application.

- DynaSteel® ensures complete protection from excessive wear on the mill lining and delivers maximum grinding efficiency. The lifter face angle remains constant throughout the life of the lining.

- DynaSteel® has proven to be successful in demanding applications, especially in primary grinding mills. The challenges faced by conventional steel liners such as cracking, are eliminated by the use of optimal materials for liner construction.

- DynaSteel® can be installed in larger mills where modern liner handlers are not available.

DynaSteel® Advantages

- Composite liner designLonger life/less liner cost per tonne

- Various steel grades & thicknessesTo achieve a uniform wear life throughout the mill

- Less weight on rotating partsLonger life of rotating parts

APPLICATION AREAS

- AG Mills

- SAG Mills

- Primary and Secondary Ball Mills

- Rod Mill Shells

- Scrubbers

Why choose us?

Why Choose Us 01

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 02

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 03

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 04

Sed quia non numquam eius modi tempora incidunt ut labore.

Advantages of DynaSteel®

Tega reinforced lifters have an integrated aluminium track to accommodate the fixing clamp. Non-reinforced Tega Lifter Bars are installed with detachable steel clamps which can slide inside the groove on the lifter base and be bolted to the mill shell. Tega Lining bolt attachment systems are compatible with conventional attachment for rubber linings used in grinding mills. The latter are available with different grades of steel as well, if required for very high or low pH-values.

FAG / SAG Mill, Primary / Secondary Ball Mill and Regrind Mill.

| Features | Benefits |

| Less wear | Life is 2-5 times compared to steel or rubber lining. |

| Less downtime during installation | Increased availability. Higher capacity utilisation. |

| Predictable wear life. | Planned shutdown, improved production. |

| Different wear pattern in different portion of the mill is addressed. | Substantial saving in downtime for avoiding replacement of parts |

| Leak proof fastening system | Better protection of mill body from corrosion |

| Less weight, easy to handle. | Reduced installation time, improved production. |

| Noise level reduced. | More environment friendly. |

| Less weight on rotating parts. | Longer life of rotating parts. |

| Safer attachment system ensures no bolt breakage. | Mill availability improves due to less maintenance and fewer and shorter stoppages. |

| Safety in installation | Weight of parts less than that of steel lining ensuring safety of installation crew as well as equipment. |

Tega DynaSteel

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.

Advantages of Tega DynaSteel

- Increase Mill availability to process more ore

- Increase Mill operation time as a result of faster relining

- Increase Life as per plant requirement

- Increase ball charge volume due to decrease in liner weight

- Lower Maintenance cost

- Lower Energy expenses

- Less personnel required for installation

- Faster reline due to lesser number of fixings for liner installation

- Do away with unplanned shut-down

- Better Liner profile stability throughout the campaign

- Installation from outside

- No chance of any fatal accident

- No use of oxy-flame inside the mill at the time of dismantling the liners

- Lower CEE required, enabling reduction in carbon footprint

- Reduces the environmental contamination by eliminating oxy-flame cutting

Tega DynaWear

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.

Advantages of Tega DynaWear

Tega DynaPulp

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.