TEGA Industries, a global leader in mining, stands out in Chile for its precision and efficiency in critical consumables for the copper concentrate production process.

In the exciting world of mining, where precision and efficiency are paramount, Tega Industries is positioned as a global leader in the creation and manufacturing of consumables for critical applications in the mineral production process. In Chile, we have left our mark on the largest mining operations in the country, providing products from the Weartec, Mill liners and Piping line, which support the efficiency and safety of operations.

The Application

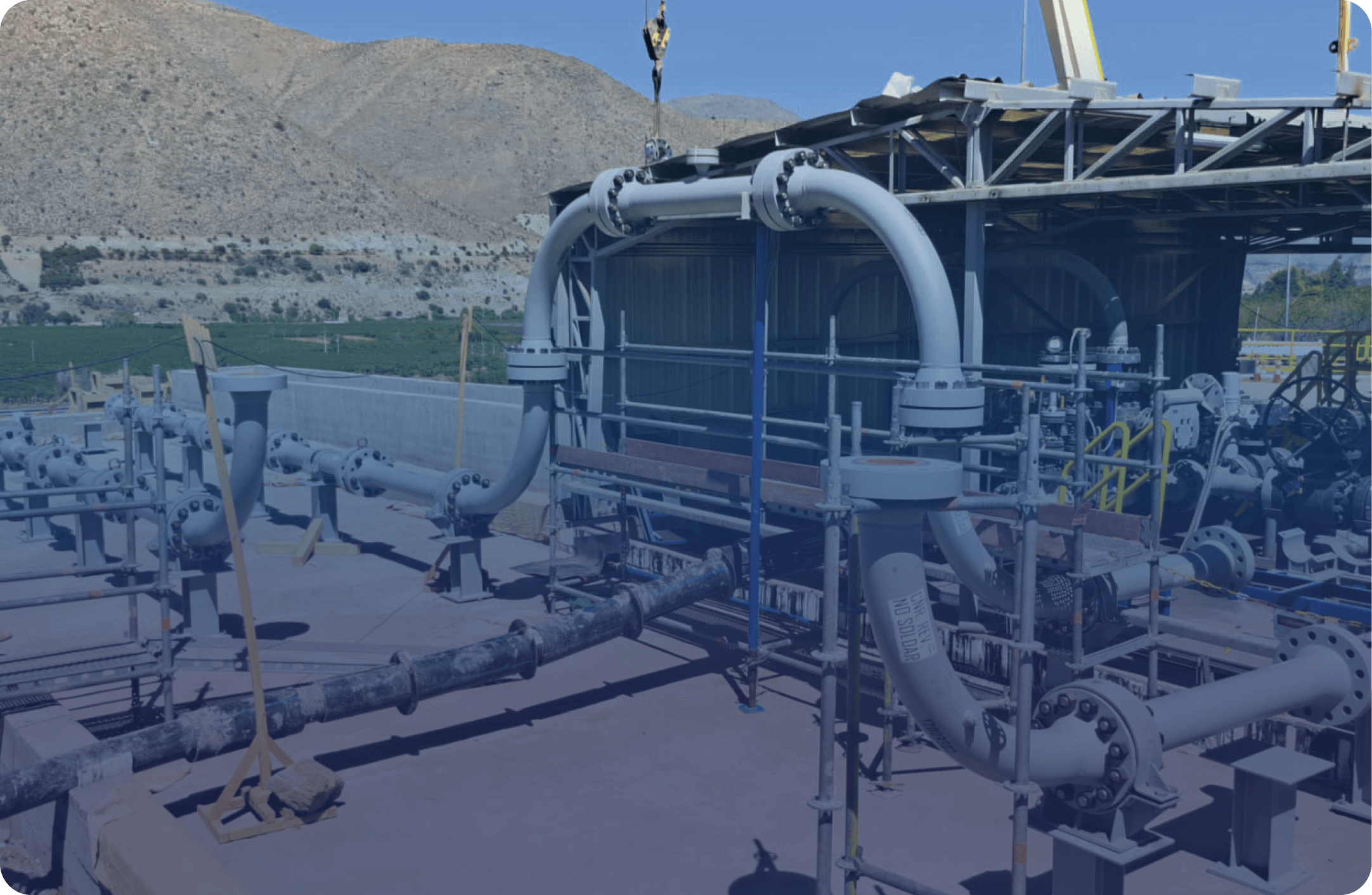

One of our recent success stories took place in a major mining operation in central Chile. The challenge: to provide a solid solution for a dissipation station, in terms of the supply of polyurethane-coated spools. The station dissipates the excess pressure generated by the difference in elevation in the sections of pipes in the concentrator pipelines. This application demands exceptional technical precision, since a failure in any of its components could compromise operational continuity.

The Challenge

At Tega Industries, we are recognized for our dedication to offering comprehensive solutions to our customers. This particular case illustrates our responsiveness to technical challenges and our unwavering will to ensure efficiency and safety, even when deadlines are extremely tight and requirements are critical.

The client requested the supply of 30 spools coated in polyurethane, a highly durable coating specially designed for abrasive fluids. However, the real challenge was not just in supply; We had to face demands that included:

A. Record Manufacturing Times

The urgency of the deadlines required a quick and decisive response. We mobilized our polyurethane-coated piping factory located in Alcalde Guzmán, Quilicura, and manufactured the 30 carbon steel units coated in polyurethane in record time. The quality of our products was not compromised at any time.

B. Engineering Capability

In collaboration with the client, we analyze the necessary plans to ensure the perfect assembly of the parts in the dissipation station. Technical precision was crucial, as any error could affect the operation of the plant.

C. Logistical Flexibility

To meet pressing deadlines, we implement innovative logistics solutions, including air freight. We monitored each stage until all the parts were in place just when they were needed for installation.

D. On-Site Technical Assistance

Our experts were present at the installation site, providing constant technical assistance to the team of installers. We verify each step of the process to ensure the correct assembly of the parts.

The Result

The result was a resounding success. Our attention to detail and ability to adapt to the client's circumstances and demands ensured that all parts were assembled smoothly. The technical inspection on site validated our supply, without observations or non-conformities. The dissipation station was activated, fulfilling its function perfectly.

A Comprehensive Solution To The Challenges Of Mining

At Tega Industries, our commitment to technical excellence and customer satisfaction is unquestionable. Our experience and knowledge in the copper recovery process allow us to provide comprehensive solutions and overcome all the challenges and requirements that the application demands. Our success story in this Chilean mining operation not only highlights our technical capacity, but also our passion for being a true partner in the mining industry.

TEGA INDUSTRIES – Partnership in Practice