Products

Aggression Ceramic Liners

Availability of low abrasion equipment

Providing the perfect solution: Our wide range of Ceramic Liners is designed for excellent performance in highly abrasive and corrosive applications. The extremely hard ceramic elements provide unsurpassed resistance to wear while the elastic properties of rubber effectively dampen the impact forces.

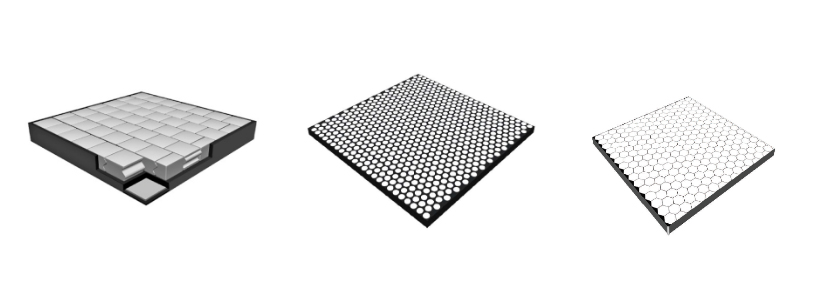

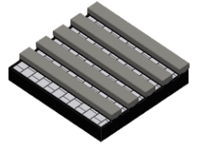

Aggression D-mac Ceraloc®

This range of liners has been developed to address the problem of high erosive wear and abrasion for fine-sized materials. It has the unique feature where the ceramic blocks are mechanically interlocked in addition to bonding with rubber in its vertical as well as horizontal faces. This eliminates any chance of dislodging of the ceramic blocks as well as helps to withstand impact load.

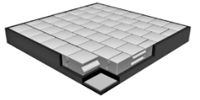

Aggression D-mac Elastocer

These liners provide supremely effective abrasion resistance for handling material with high cohesive property and high abrasion index. The Elastocer variety has cylindrical ceramic tiles embedded in rubber matrix to resist abrasion.

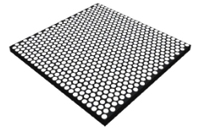

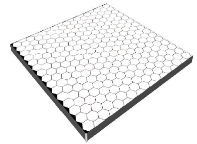

Aggression D-mac Ceraflex

This range of liners provides excellent resistance to abrasion and enhances flow promotion thanks to the ceramic tiles being hexagonal in shape. This enhances the ceramic area that is exposed.

Aggression D-mac Ceraflo

This is a ceramic, rubber composite liner that is mainly used for flow promotion, with an added benefit of longevity and low weight. The main advantage of this liner is the fact that it can be fitted in curved surfaces like pipes by pasting them with adhesives.

Aggression D-mac Cerahard

This type of liner is a combination of high hard steel, ceramic and rubber which is specially designed to handle materials that involve both lumpy and fine material.

Aggression D-mac Prime

This range entails the combination of special high-grade ceramic tiles having more resistance to impact and wear than any conventional regular ceramic liners.

Aggression D-mac Zeta

This is our innovative and patented heat resistant liner range, having composite liner construction of high hardness interlocked ceramic embedded within high hard steel. This product addresses the problem of high erosive wear and abrasion for sized or fine material in high temperature zones. It has the unique feature where the ceramic blocks are mechanically interlocked, thereby eliminating any chance of dislodging of the ceramic blocks.

Advantages of Aggression D-Mac Zeta- No dislodging of ceramic blocks due to interlocking design

- Resistance to heat

- Resistance to abrasive wear

- Reduced time for installation

- Low Maintenance

Why choose us?

Why Choose Us 01

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 02

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 03

Sed quia non numquam eius modi tempora incidunt ut labore.

Why Choose Us 04

Sed quia non numquam eius modi tempora incidunt ut labore.

Tega DynaSteel

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.

Advantages of Tega DynaSteel

- Increase Mill availability to process more ore

- Increase Mill operation time as a result of faster relining

- Increase Life as per plant requirement

- Increase ball charge volume due to decrease in liner weight

- Lower Maintenance cost

- Lower Energy expenses

- Less personnel required for installation

- Faster reline due to lesser number of fixings for liner installation

- Do away with unplanned shut-down

- Better Liner profile stability throughout the campaign

- Installation from outside

- No chance of any fatal accident

- No use of oxy-flame inside the mill at the time of dismantling the liners

- Lower CEE required, enabling reduction in carbon footprint

- Reduces the environmental contamination by eliminating oxy-flame cutting

Tega DynaWear

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.

Advantages of Tega DynaWear

Tega DynaPulp

Tega DynaPrime range has been designed specifically for the bigger size of the mills where modern liner handlers are available. Tega DynaPrime has been engineered to reduce the number of pieces being installed inside the mill, substantially reducing the installation downtime for maximum mill operation up-time.

Tega DynaPrime puts safety above all and has taken measures to render the reline site safe. Bolting from outside and lesser weight of the lining considerably reduces any risk during the installation of the liner.